Modifications to the

Phantom sails

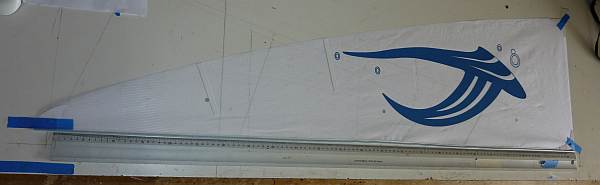

It is worthwhile making this first check before setting up the

yacht to see if there is an issue with the luff on both the main

and jib. Stretch each sail out on a flat table and tape

each corner out with just a slight tension on each. Lay a

straight edge along the luff of each sail. There should be

a regular convex curve of about 4mm - 6mm for the sail to set

properly. If there is a concave curve or a variable one

then the sail will not set effectively and should be modified to

produce that curve.

Modifying Mainsail Luff

¦¦

Modifying Jib Luff

¦¦

Improving the sail shape

¦¦ RC Yacht Supplies

Modifying the mainsail

My mainsail was a typical example with a concave curve of about

4mm. Needless to say when I had tried to set it on the

mast, it had little shape, the leech would fall off, creases

would appear across the sail and it sailed abominably

To deal with this I decided to replace the folded and sewn

section with hanks as in full sized yachts that travel in the

luff groove with the sail completely outside of the groove.

This would make fitting the sail easier as I found feeding it

down the mast groove a little difficult.

The first step is to undo the stitching ('quickunpick' from my

partners workshop). Then the sail material is laid flat

and carefully stuck down with masking tape so as not to move the

rest of the sail material. A light wooden batten is laid

along the luff and using weights and clamps forced into regular

convex curve. Use a straight edge to check the amount of

curve - about 4mm - 6mm seems about right. It is probably

better to have the maximum part of the curve higher up the sail

say at about 60% of luff height. To ensure the sail area

is not affected the maximum part of the curve was made to touch

the line of stitching. This meant that the curve runs over

the two reinforcing stuck on plastic patches. These need

to be carefully removed along with the eyelets set in them.

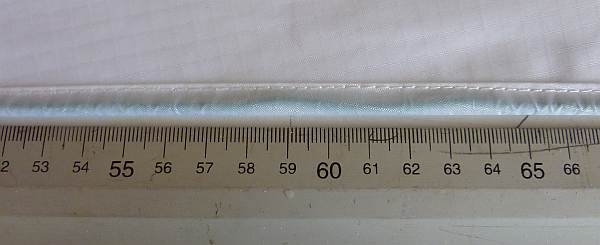

The curve is transferred to the cloth using a fine point

permanent marker. The cloth may then be folded along the

line at this point and stitched back down to reinforce the

leading edge or be reinforced using some Mylar tape and then cut

off. I much prefer the tape method. This tape is

available from RC yacht suppliers in their sail making section.

With the sail still fixed to the table, the tape is

applied to the sail just touching the line or slightly

overlapping it. This is repeated on the other side.

The sail material is trimmed to the line using a

sharp blade cutter and straight edge working a small section at

a time and maintaining the straight edge as close as possible to

the line. Always cut with the straight edge over the material of

the sail and the exposed section is the material to discard.

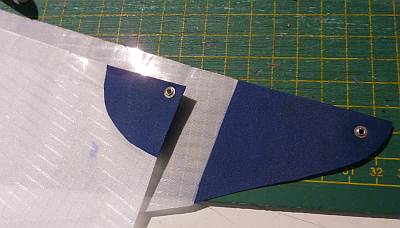

The corners of the sail are reinforced with sticky backed sail

repair cloth. Two layers are necessary making the second

overlap the first by a small amount. Two eyelets are then

set in the reinforced section.

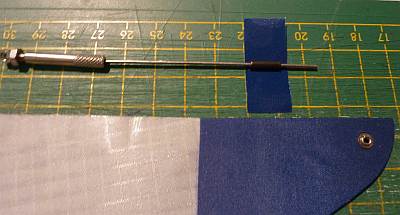

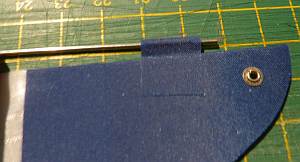

The slides for the mast track are made using a

ferrule from a fishing supply shop (the ones used to secure wire

fishing trace) and a small piece of the sticky sail cloth about

35mm X 12mm. Remove the backing sheet and lay the ferrule

across the middle of the sticky side. Lay the edge of the

sail over one edge so the ferrule remains about 2mm proud.

Let the sail grab the sticky material and holding the ferrule

with a wire fold the other side over the ferrule and onto the

sail. Roll the ferrule between fingers makes a neat finish to

the slide. About 6 or so slides are necessary, one near

the head another near the foot and the rest evenly spread.

Modifying the Jib

If modification is necessary then the jib is treated in much the

same way. Once the ferrules are in place a fine wire or

thread is passed through each to act as a forestay. I

prefer to use a wire forestay and make a channel for it by

sticking a luff tape around the luff using double sided sticky

tape. The materials for this are available from RC yacht

suppliers. This process is outlined on the Stirling site

on this page

http://www.stirling.saradioyachting.org.au/saildesign/finishingsail.htm

near the bottom.

Improving the sail shape

Despite the addition of the luff curve the sail still suffers on

its overall shape. The leech of the mainsail is

particularly difficult to support and not have it fall off and

deliver no drive - just drag. Normally shaped seams

increase the sail area in the middle of the sail effectively

making the leech tight when the clew is tensioned. Try

tensioning your clew and what happens is a diagonal crease from

the leech to somewhere on the mast. The leech cannot be

tightened. One way of dealing with this in a flat panel

sail is to reduce the actual distance along the leech by ever so

slightly crinkling it up with thin tape. Tape the sail on

a flat surface so the leech is held firmly in position.

carefully lay some 4mm sail edging tape from the head to the

clew positioning it right at the edge. Lay the tape with

just a slight amount of tension and firmly press it down.

Releasing the sail and supporting it by the head, tack and clew

should now show the sail to have a curve from the luff to the

leech. If the leech is too tight it will curl in too much.

Simply repeat with less tension with some new tape.

The slight amount of curving at the leech will need to be

removed or flattened with battens so the curl in the sail leech

moves forward to the body of the sail. I recommend at

least 4 battens. I have these about 1/3 of the chord and

fairly rigid (more so than the ones supplied) and available from

the RC yachting suppliers. A taper over their length and a

piece of reinforcing tape over their inner end end helps to

encourage a smooth transition from a straight leech to curved

sail body. You may need to try a few times to get things

right. look at the images below to see how the sails can

look with this treatment. The black and yellow bands are

there simply to show the curve in the sail and form no function

in generating shape.

RC Yacht supplies

See the left hand column in the links page

under the 'Play the Rules' section, the three most useful

suppliers are listed with links to their address and on-line ordering web sites (click on logo image).

page

last edited on

04/05/2025