Modifications to Waterproof

the Hatch on the

Phantom Yacht

Water proofing the hatch

There

are as many ways to do this as there are yachts!

I have glued in

a false lower deck (see it taped in place in the photo) with the

centre section removed then a separate hatch sits on the this

flat surface supported by some flanges glued to the bottom edge.

This way the removable hatch is at the same level as the new sub

deck and taping over the join will seal it quite well. I

also intend to drill a hole in the top deck near the steering

position and seal with a bung or piece of sticky backed sail

cloth to assist draining the water from the hull in the then

unlikely possibility of water getting in - well maybe!

Warren

has a method that seems to work involving a solid plank laid

fore and aft over the electrics but under the deck. Two

metal threads secured in this plank are directed up through

holes drilled in the original hatch cover. when tightened from

the top with two wing nuts on the metal threads, the hatch is

pulled down tight and seals well on the foam.

Warren

wrote - Following are the hatch cover mods I made to my Phantom,

I have since then had no ingress of water through this part of

the boat.

Materials used:

1. 10x10mm 500mm long closed cell foam cut from a camping or gym

mat, 2. 30x200mm ~4mm 3 plywood, 3. 2x 3/16x1'' SS countersunk

machine screws with 2x nuts plus 2x wing nuts, 4. 2x 3/16"

rubber O'rings.

Note:

1. Position of first SS screw must allow lower support brace to

clear hatch opening when being installed below the deck, please

check before drilling.

2. Instead of the SS (Stainless Steel) bolts and nuts etc, you

could use nylon.

3. Optional closed cell foam installed between hatch and lower

support brace allows battery wiring to transit without

interfering with the main sheet servo cable.

4. Lightly grease the 3/16" O-ring once installed.

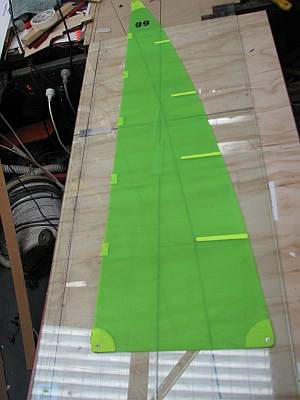

Mal our member from Vic (Bendigo) has shared his method of

sealing the hatch and a few photos from his efforts of sail

making and a couple of shots on the water.

First I removed the totally useless open cell foam from the

hatch cover as well as the double sided tape, leaving clean

white plastic.

Because I want to leave the hatch sealed the entire day the

waterproof toggle switch and LED is fore of the hatch in place

of 2 decorations.I use a turnigy 9X as a radio and have found

the short antenna works fine, even at great distance on the

water ( from a sailing point of view) if it's fitted inside the

hull around the centreline.To accommodate that and the bare

bones Tx ( no cover, easier to keep dry in case of a mishap) I

mount them under a false hatch insert made from 6mm depron (

only because I have plenty).This fits flush, and tight, in the

hatch opening.Next I prepare 3 strips of 48mm wide Norton pipe

and sealing tape (Bunnings..about $4.50..

Bit

like duct tape but far less stretchable.. Bit "cushion" like..)

and lay this over the depron and down across the hatch

surrounds.Using a better hatch toggle ( made from large servo

arm) this applies just enough pressure on the hatch so that the

membrane of tape fits pretty well as a gasket under the hatch.

But, the membrane provides a total barrier regardless so it even

works fine without the depron filler.I've had the Phantom out in

all sorts of conditions including a rather wild session 10 days

ago when the wind was going 20 -26 kph gusting to high 30's.. We

add strip lead above the bulb ( I have 1700g ballast (nett) to

bring it up around 1800 -1900g ( plus bulb 63 grams) just to

sail at all in this weather. I know that I should be using storm

sails instead of more weight but that's a little further up the

list.Works for us.. Water is counted in drops these days.. Wish

it were so on all the boats.The beauty of the method is that

it's easy to do and other than removing the foam it doesn't

alter the boat at all.Anyway, most rc sailboaters seem to all be

" I'd rather do it my way" so this is offered only should it be

of any interest to someone, possibly a Phantom owner with water

probs.Oh.. I added a hole near the stern and glued a brass nut

on top to take a brass screw. I'm a compulsive water "checker"..

Too many scars not to be. This way its simple to check after the

boat is tilted aft.

Bit

like duct tape but far less stretchable.. Bit "cushion" like..)

and lay this over the depron and down across the hatch

surrounds.Using a better hatch toggle ( made from large servo

arm) this applies just enough pressure on the hatch so that the

membrane of tape fits pretty well as a gasket under the hatch.

But, the membrane provides a total barrier regardless so it even

works fine without the depron filler.I've had the Phantom out in

all sorts of conditions including a rather wild session 10 days

ago when the wind was going 20 -26 kph gusting to high 30's.. We

add strip lead above the bulb ( I have 1700g ballast (nett) to

bring it up around 1800 -1900g ( plus bulb 63 grams) just to

sail at all in this weather. I know that I should be using storm

sails instead of more weight but that's a little further up the

list.Works for us.. Water is counted in drops these days.. Wish

it were so on all the boats.The beauty of the method is that

it's easy to do and other than removing the foam it doesn't

alter the boat at all.Anyway, most rc sailboaters seem to all be

" I'd rather do it my way" so this is offered only should it be

of any interest to someone, possibly a Phantom owner with water

probs.Oh.. I added a hole near the stern and glued a brass nut

on top to take a brass screw. I'm a compulsive water "checker"..

Too many scars not to be. This way its simple to check after the

boat is tilted aft. The

battery was a a test of using current weight but move it from

before the servo holder to the stern. Worked and stopped

broaching but made the boat vert twitchy as the bow was just out

of the water at rest. Waves slap seemed to be the problem. It's

since been moved back inside but immediately aft of the servo

holder. Seemed to be nicely balanced Monday going by the ease of

tacking and gybing as well as pointing high.

The

battery was a a test of using current weight but move it from

before the servo holder to the stern. Worked and stopped

broaching but made the boat vert twitchy as the bow was just out

of the water at rest. Waves slap seemed to be the problem. It's

since been moved back inside but immediately aft of the servo

holder. Seemed to be nicely balanced Monday going by the ease of

tacking and gybing as well as pointing high.

Thanks for all your help through the club site,

I'm right into sail making now and will send you and update when

I do some more testing.It's light spinnaker rip-stop. Cut with

soldering iron from template.The light wrinkles disappeared

completely while under way. I used your advice of the luff and

battens.A long way to go , yet.

I'm right into sail making now and will send you and update when

I do some more testing.It's light spinnaker rip-stop. Cut with

soldering iron from template.The light wrinkles disappeared

completely while under way. I used your advice of the luff and

battens.A long way to go , yet.

page

last edited on

04/05/2025