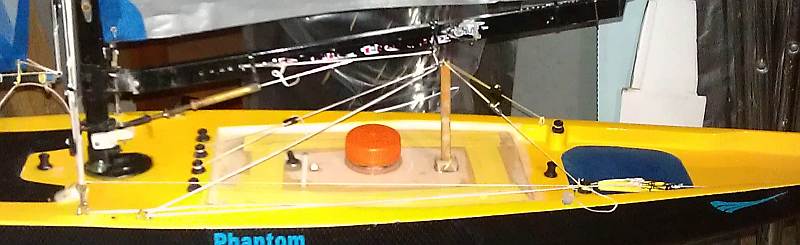

Modifications to Main/Jib

sheeting system on the

Phantom Yacht

General Introduction

One of

the many frustrating things about the phantom is the sheeting

system used to control the main and jib sheets. While the

winch is OK - quite powerful and not too slow, the sheets are

held in place on the drums by a close fitting plastic shroud.

When under tension from the wind, the system works fine but if

the conditions are light then as the sails are let out the turns

on the drums do not run out of the shroud and wind over

themselves. This often means that the next time the sails

are pulled in the sheets pull in much further than they should

often with the jib and main sheets no longer in sync - bad!.

The way

to overcome this is to maintain a constant tension on the cords

which wrap around the drum

Version 1 - Ben M is a complete loop

system involving both winch drums and a rubber band in the loop

to maintain tension.

Version 2 Paul H is a simpler system using

only one drum and a length of shock cord to maintain tension.

Version 3 Bob Edgecombe is a quite

sophisticated but elegant solution to this problem

Version 1

One of the simplest ways of doing

this is to make a continuous loop which winds up on one drum and

winds out on the other.

Note

that the cords wrapped around the drums are now in opposite

directions exiting on the same side. The line is joined by

coiled spring or rubber bands slightly stretched to maintain

tension in the loop. I have used silicone rubber bands as

used in cooking as these are UV resistant and don't perish.

The loop is set up so that when the sail control is fully in the

spring is near one end. The lower drum has about 5 turns

while the top drum only 1 or 2 turns. This means when the

sail control is set to the fully out position, the spring moves

to the other end of the top part of the loop with 5 or so turns

on the top drum and 1 on the bottom. This gives about the

300-350 mm of movement needed. The main and jib sheets are

both attached to the end of the spring nearest the bottom drum -

important!. This means the bottom drum takes all the

strain of pulling the sails in. This is good as this drum

is nearest to the bearing in the winch and reduces wear.

The top drum simply maintains tension in the loop.

The

drums and bottom part of the loop are below decks while the

spring and top part are above deck. The turning mechanism

at both ends of the loop are about 400-500 mm apart.

While

it's possible to buy small deck blocks for turning the loop I

chose to use the easier and cheaper option of bending fine brass

tubing into a 180° hook and

belled the two open ends with a fine punch. The cord is fed

through the brass and slides with surprisingly little friction

using spectra or dyneema cord.

While

it's possible to buy small deck blocks for turning the loop I

chose to use the easier and cheaper option of bending fine brass

tubing into a 180° hook and

belled the two open ends with a fine punch. The cord is fed

through the brass and slides with surprisingly little friction

using spectra or dyneema cord.

While I made a former to assist

this bend by channelling a groove around a piece of plastic,

bending it gently around a thumb can work OK. Aim for

about a 20mm diameter curve. The brass tube is fed through

a small hole drilled in the deck and the loop set up with

tension. This holds the brass in position which can then

be glued in position.

by channelling a groove around a piece of plastic,

bending it gently around a thumb can work OK. Aim for

about a 20mm diameter curve. The brass tube is fed through

a small hole drilled in the deck and the loop set up with

tension. This holds the brass in position which can then

be glued in position.

Because both main and jib

sheets attach to the cord and are pulled in the same direction,

one of them will need to be redirected back to reach the boom

sheeting position. I had one brass turning loop near the

transom and the other near the mast position giving me the 45mm

I needed. This means there is a direct pull set up for the

jib but the main needs to go forwards around a turning point

near the mast then back to the main sheeting point.

This does require a new

sheeting point for the main and jib. The jib is easy as

the existing outlet could be used with a metal loop glued in it

while the main sheeting point has previously been discussed in

the 'Mainsheet Fairlead' page

previously

The only other change was to

slightly alter the direction the tension cord enters the top

drum as it was angled up a little too much to ensure it didn't

ride off. See the image to show one way of doing this.

Does it

work? Definitely! No more pulling the sheets in to

find they go too tight, no more letting the sheets out and not

having them move far. The booms go exactly where they

should according to the control on your radio in even the

gentlest of breezes.

Version 2

Thanks to Paul H for this system. It is simpler to

construct as there is only one exiting point rather than two

with the sheet wrapping around the bottom drum only running to

the rear of the deck and exiting via a tube similar to the above

method.

The sheet now runs aft around a turning block then forward

sufficiently to allow main and jib sheet attachment and ends

with a length of hat elastic or similar carried all the way

forward to maintain pressure on the sheet and keep it on the

drum.

The sheet now runs aft around a turning block then forward

sufficiently to allow main and jib sheet attachment and ends

with a length of hat elastic or similar carried all the way

forward to maintain pressure on the sheet and keep it on the

drum.

The

jib sheets are led forward direct to a jib sheet fairlead set

into the original jib sheeting exit point while the mainsheet is

led forward to a turning point using one of the shroud

attachments and back to the mainsheet fairlead.

Paul

has used this system only the once so far with no issues (and

won the day!). It certainly seems to be the simplest way

to solve the poor original sheeting system.

Version 3 thanks to Bob Egdecombe

This

version like version 1 uses the two winch drums to wind a loop

of cord in and out around a turning block. The

interesting idea here is its all under deck. An inspection

hatch was cut out near the front of the yacht and a turning

block secured there. The open area is later covered with

stickyback sail cloth. A loop in the cord allows the two

sheets to be attached and during sail pull in are dragged

forward. The mainsail cord goes directly to the existing

mainsheet exit fitting (through a wire loop just to keep it in

position) while the jib sheet loops back through a wire loop

then back to the existing jib sheet fitting. The need to

loop the jib sheet around a wire loop is to ensure enough

movement is obtained in the jib sheet (~ 30 cms or so).

Notice that this does not use the winch drum cover - never a

good idea!!

This

version like version 1 uses the two winch drums to wind a loop

of cord in and out around a turning block. The

interesting idea here is its all under deck. An inspection

hatch was cut out near the front of the yacht and a turning

block secured there. The open area is later covered with

stickyback sail cloth. A loop in the cord allows the two

sheets to be attached and during sail pull in are dragged

forward. The mainsail cord goes directly to the existing

mainsheet exit fitting (through a wire loop just to keep it in

position) while the jib sheet loops back through a wire loop

then back to the existing jib sheet fitting. The need to

loop the jib sheet around a wire loop is to ensure enough

movement is obtained in the jib sheet (~ 30 cms or so).

Notice that this does not use the winch drum cover - never a

good idea!!

page

last edited on

15/10/2024