Modifications to Mainsheet

Fairlead on the

Phantom Yacht

Mainsheet fairlead

The

issue here is that when viewed from the side of the yacht, the

jib sheet fairlead is directly under the jib boom fitting where

the sheet is attached or fed through. The main fairlead is

at least 70mm behind the equivalent position on the main boom.

This is clearly done because the area where the fairlead ought to be

is the deck opening or hatch cover. This leads to

incorrect geometry for allowing the main boom and the jib boom

to move out together and end up both at right angles to the

hull. A variety of methods can be employed to correct this

situation.

One is

to use a system of three cords and a ring adjusted so that the

ring is directly under the main boom attachment point. The

disadvantage of this is its a little tricky to adjust and the

ring is not supported in a vertical sense very well and can move

up and down changing the boom angle. It is easily removed

providing access to the hatch area.

One is

to use a system of three cords and a ring adjusted so that the

ring is directly under the main boom attachment point. The

disadvantage of this is its a little tricky to adjust and the

ring is not supported in a vertical sense very well and can move

up and down changing the boom angle. It is easily removed

providing access to the hatch area.

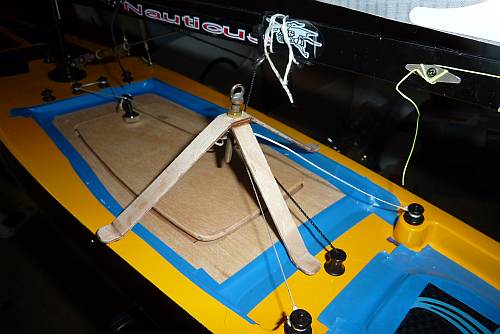

Another method is to use a solid bridle or rod with a ring at the

end to feed the mainsheet through. Again because of the

hatch, fitting a rod is difficult as it would have to be angled

well forward from a solid deck are passing through the deck and

secured - glued - to the hull floor. The bridle is the

easiest choice made of aluminium or thin ply and secured at the

deck either side of the and on the floor of the deck behind the

hatch. The one shown is ply reinforced with a layer of

carbon fibre rovings on the underside. Small self tapping

screws would hold the bridle as the forces are mostly sideways.

Another method is to use a solid bridle or rod with a ring at the

end to feed the mainsheet through. Again because of the

hatch, fitting a rod is difficult as it would have to be angled

well forward from a solid deck are passing through the deck and

secured - glued - to the hull floor. The bridle is the

easiest choice made of aluminium or thin ply and secured at the

deck either side of the and on the floor of the deck behind the

hatch. The one shown is ply reinforced with a layer of

carbon fibre rovings on the underside. Small self tapping

screws would hold the bridle as the forces are mostly sideways.

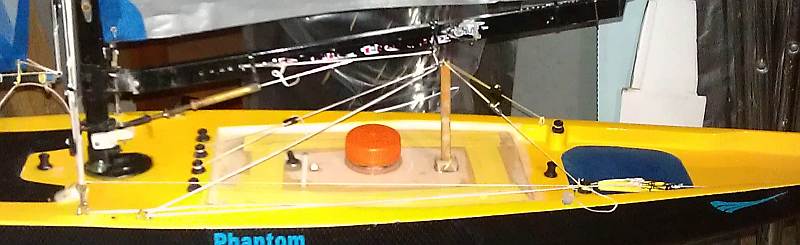

In

the end, the method I have settled on is to use a wooden rod

held vertically beneath the sheeting position by making a small

wooden dam to support the base of the rod on the hatch cover and

held in place by three lines tensioned with bowsies. A

ring is used at the connection point at the top of the peg for

the supporting lines and also serves as the ring through which

the main sheet passes. The top of the rod is grooved so

that the ring lies firmly and the lines lead cleanly away.

This has the advantage of being easily removed from the hatch by

loosening the bowsies and removing the forward line which is

just looped around two of the cleat fittings in front of the

hatch cover. The rear two lines are tied more permanently

to the two rear cleats so the whole fitting does not become lost

and is readily replaced. The screw cap seen in the image

below allows access to a plug connected to the battery which

allows it to be charged without dismantling the whole

arrangement. This is OK as the yacht no longer leaks yet

allows the hull to be aired through the open cap hole. The

screw cap is from a small fruit juice bottle where the neck is

cut off and glued to the hatch cover.

page

last edited on

04/05/2025